Marine Engineering and Mechanical Failure Services

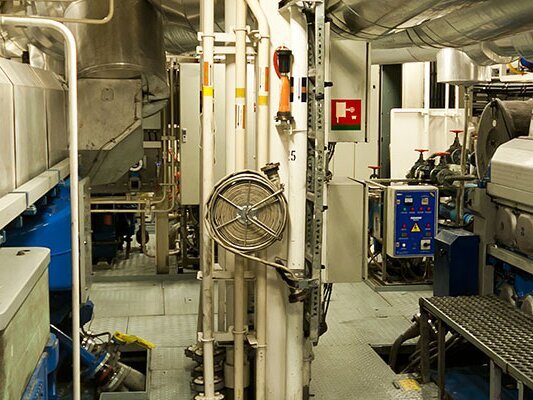

The maritime industry employs a truly diverse range of machinery, components, and assets. From the vessels themselves to ports, there are innumerable moving parts that can all be subject to damage, friction, wear and failure.

It’s for those reasons that maritime businesses of all kinds can benefit significantly from applying mechanical engineering best practices.

Why? Because machinery, component and asset failures can be costly, result in litigation and more. So, if you find yourself dealing with a maritime machinery failure, call upon the expertise of Neale Consulting Engineers.

Examples of failures investigated by Neale Consulting Engineers are detailed below.

Marine engine failures

With main engine failures being incredibly costly, it’s vital that you are able to establish the facts as to why an incident has occurred. Neale Consulting Engineers has investigated a range of engine failures, with reasons for failure including:

- Bearing failures

- Camshaft wear

- Piston ring sticking

- General wear and material degradation caused by lubrication and filtration deficiencies

We have also - in some instances - identified design deficiencies which have correlated with failures. In these instances, Neale Consulting Engineers was able to provide advice on design improvements.

Internal combustion engine failures

Aside from the main propulsion engine, many vessels utilise internal combustion engines of various types to power ancillary systems and equipment.

But, like main propulsion engines, these diesel, petrol (gasoline), and natural gas powered engines can be subject to wear and friction related failures.

At Neale Consulting Engineers, we have investigated a range of engine-related issues, including piston ring and cylinder liner wear, bearing failures, crankshaft failures, camshaft failures and other issues. We have conducted these investigations on behalf of both manufacturers and end users.

Engines studied have included; generator engines, and slow speed marine two-stroke diesel engines.

Deck crane failures

Deck cranes - be they foldable knuckle boom cranes, telescopic boom cranes, stiff boom cranes, or any other type of deck crane for that matter - are subjected to considerable loads, stresses and strains throughout their operation.

As a result, they can suffer the same types of wear and friction related failures as other types of maritime equipment.

Neale Consulting Engineers has investigated multiple deck crane failures, with many being attributed to the failure of slewing bearings and jib heel bearings.

However, we’d advise that deck cranes be assessed on a routine basis - given that their failure can result in the catastrophic toppling of the whole crane, or collapse of the jib - with the attendant risks to life that these scenarios entail.

FPSO turret system failures

Floating production storage and offloading (FPSOs) vessels require the use of turret systems in order to remain anchored in place for production purposes.

With the turret being used for mooring purposes (and to allow the FPSO to make rotations where necessary), it can be subject to considerable forces. As a result, tribological principles apply - insufficient lubrication, improper surface interaction, and material degradation can result in the failure of the turret.

Neale Consulting Engineers has investigated exactly this type of failure. Our investigation concerned the failure of a FPSO turret supported on a multiple wheel and rail turntable. Upon investigation, it was discovered that failure was due to poor lubrication. With improper lubrication, frictional forces became magnified, causing the rollers to mistrack, damaging the rails and jamming the turntable.

Thruster gearbox failures

Thrusters are an integral part of modern vessels of all types - allowing for precise manoeuvring. However, thrusters can be subject to the types of friction and wear-related failures that afflict other types of machinery.

Neale Consulting Engineers has investigated a slew of thruster gearbox failures. Our investigations have typically revealed deficiencies in the strength and flexibility of various components; this, in turn, results in the reduced lifespan of bearings and gears - terminating in failure.

Marine engineering and mechanical failure consultancy services

Whether you want to proactively apply engineering best practices, or require the investigation of a machinery failure, choose Neale Consulting Engineers.

Established half-a-century ago, Neale Consulting Engineers boasts enormous experience in applied engineering and tribology, working over 800+ assignments.

Contact us today for further information on how we can help you.

In need of marine engineering or mechanical failure assistance?

Then contact us now for a free, no-obligation consultation.